On 23rd February 2024, CCEP jointly completed the acquisition of CCBPI. Some information on this page will be updated in due course to reflect the addition of the Philippines to our business.

We’re taking urgent action to reduce the impact of our packaging. We have a responsibility to help tackle the packaging waste crisis and understand the urgency and complexity around plastic pollution. By reimagining the way we do business, we are progressively moving away from a linear model and the waste it creates.

Systemic change needs collective action. So we partner with wider industry, government and NGOs to advance on our journey towards a World Without Waste.

Our focus is clear: reduce, reuse, recycle. We need to find innovative ways of doing more with less. That includes accelerating innovation to deliver drinks in new ways, like reusable packaging and smart dispensers. And it needs to happen across every part of the packaging journey. From the design of the packaging itself, to the way in which it’s made, used and treated after use. We are removing materials where we can and making sure all the packaging we do use is collected, recycled and reused in a low carbon circular system.

We are redesigning and reimagining every aspect of how we deliver drinks, to be as resource efficient as possible. And ensure nothing is wasted.

Less new materials. Less greenhouse gases. And less waste.

Our actions support UN Sustainable Development Goal 12: Responsible consumption and production and Goal 14: Life below water.

Our progress in 2023

Recycled plastic (rPET) milestones

Our strategy is simple – we will reduce our use of packaging where we can and ensure that the equivalent of all the packaging we do use is collected, reused or recycled so that it does not end up as waste or litter. We aim to achieve this through the key pillars of our packaging strategy:

Our position on

- Recyclability

- Extended Producer Responsibility

- Collection

- Reuse

- Recycled Plastic

- Chemical Recycling

Why it matters

Recyclability is the first principle of the circular economy. To enable packaging to retain its value and for material to be recycled, it must first be collected and be compatible with recycling infrastructure in practice and at scale. That’s why we are working hard on the three key elements of recyclability: design, collection and recycling.

Our approach

Circularity begins with designing out waste1. This means designing our packaging to be technically recyclable so that it can be reused or recycled to make new packaging. But this is only the first step. It doesn’t mean it will get recycled.

For this to happen, we must also make sure that effective collection systems are in place to collect that specific packaging type in practice and at scale. This means that, in each market in which CCEP operates, there are formal or informal collection systems available that cover significant and relevant geographical areas as measured by population size.

Once it is collected, this packaging design needs to be compatible with the recycling processes that are in place in each country so that it can be effectively sorted, recycled and used again. This ensures the packaging material maintains its economic value and prevents it becoming waste.

It is important too that any closures, labels, sleeves, inks, laquers or coatings don’t hinder or prevent packaging from being recycled. This means that they must be able to be separated and removed from the recycling process.

CCEP would like to see bottles and cans stay in the ‘circular loop’ to be made back into bottles and cans or to have multiple use cycles. There is still some way to go on this as there is demand from other industries for this high quality recycled PET and aluminium. This means that some of the PET bottles that are collected for recycling are downcycled into other materials (such as fibre, plastic strapping etc.). The resultant downcycled material can be hard to recycle again, which removes it from the circular economy.

We would like to see all bottles and cans have better circular outcomes than this. This is why support the principle of ‘priority first access’ for the beverage industry for PET and glass bottles and cans so they can go round and round in a circular loop.

We not consider packaging which can only be sent for incineration with or without energy recovery or sent to landfill to be recyclable.

Why it matters

Extended producer responsibility (EPR) is an environmental policy approach used by governments to ensure that companies who put packaging on the market – referred to as the producer - pay for its collection, sorting, and recycling after use.

To stop packaging waste and pollution, we need to create a circular economy for packaging. However, there is often an economic barrier to overcome as the collection, sorting, and recycling of packaging typically costs more than the value generated from the recycled materials.

This is why CCEP supports the Ellen MacArthur Foundation’s statement on EPR and the EU Commission’s minimum requirements for EPR. It is a proven way to provide the right level of ‘dedicated, ongoing’ funding to support the scaling of packaging collection and recycling solutions so that packaging no longer ends up in the environment

Our approach

CCEP supports the Consumer Good Forum design principles for Optimal EPR as well as for Ecomodulation of EPR fees. Eco-modulation means that EPR fees should consider the cost to collect and sort each packaging format for recycling based on the recyclability and material type as well as the overall ‘net cost’ of the collection, sorting and recycling. This ensures that each material ‘pays its own way’ and cross-subsidisation of packaging materials is avoided

What does ‘net cost’ mean?

EPR systems should operate on a net cost basis, meaning the EPR fees should reflect the revenue that is generated by the sale of materials for reprocessing. The market value of a given material may relate to its recyclability but not necessarily; market values are driven by many factors, including the prices of virgin alternatives (source: Consumer Goods Forum)

An additional benefit of eco-modulation is that is provides an incentive to increase the recyclability of packaging formats. CCEP recognises that circularity starts with designing for recyclability and we are committed to making our packaging 100% recyclable by 2025.

How EPR schemes are designed and implemented are critical to their effectiveness. In markets where waste management infrastructure exists, CCEP supports the principle of ‘mandatory, fee-based EPR schemes, in which all industry players introducing packaging to the market provide funding dedicated to collecting and processing their packaging after its use.’1 In these markets, beverage packaging return schemes are the most efficient form of EPR scheme.

However, this approach may not be appropriate for all packaging formats in all markets so local context is critical to the design of the optimal EPR scheme in each market.

In markets without comprehensive waste management infrastructure, CCEP advocates for legislation that drives multi-stakeholder action (we call this extended stakeholder responsibility or ESR) based on optimal EPR principles and that supports both formal and informal collection. In these markets, an equal partnership between government and the private sector is critical to drive the necessary establishment of waste management infrastructure and consumer education on the segregation of waste on which optimal EPR design depends.

Why it matters

None of our packaging should end up as litter. Collecting packaging for recycling once it has been used is critical to creating a low carbon, circular economy and keeping plastic out of the environment. That’s why CCEP is supporting the creation of collection solutions in all our markets, working with national and local governments and stakeholders.

Our approach

We are committed to achieving our collection goals and aim to collect a bottle or a can for every one we sell by 2030 so that beverage packaging can be recycled and reused.

Addressing collection and infrastructure challenges is often complex and collection solutions vary depending on the socio-economic and legislative context in each market. They include extended producer responsibility (EPR) schemes, such as beverage packaging return schemes and kerbside collection, which are driven by legislation. They also include directly funded voluntary action to invest in local collection systems to drive progress towards both our and the wider industry’s collection goals.

In markets where collection infrastructure is often well developed, like Europe, Australia and New Zealand, CCEP supports legislation for well designed, industry-run beverage packaging return schemes, unless a proven alternative exists.

Whilst the term used to describe these schemes varies per market (in Europe, they are called Deposit Return Schemes, in Australia, Container Deposit Schemes), the principle is the same; it places a value on our packaging and aims to incentivise consumers to return it. Whilst there are many already in operation in which we play an active role, we are also working closely with governments in Europe, Australia and New Zealand on establishing beverage packaging return schemed schemes.

In markets where collection infrastructure and legislation is less developed, such as Indonesia, the Pacific Islands and Papua New Guinea, CCEP is committed to proactive voluntary action and aims to directly fund collection solutions to recover used beverage packaging and drive circular economy outcomes while also as acting as a “catalyst” for wider industry and government action on managing waste collection at scale.

CCEP takes this voluntary action alone where needed to drive progress towards our goals in each market. Our preference is to collaborate with government, NGOs and beverage industry stakeholders in each market as we believe that together we can go further to drive collection and circularity at scale.

Why it matters

Reusable packaging is packaging designed to be used multiple times for the same purpose for which it was conceived. Reusable beverage packaging is either a packaging format that is used by the consumer and then returned so that it can be refilled again by the producer (returnable-refillable) or any drinks dispensing system where a consumer uses a reusable container (refillable).

Redesigning how to bring products to people in new ways, like reusable formats, is an effective way of reducing single use plastic use and becoming more resource efficient in the materials we use. Reuse therefore complements the progress being made on beverage packaging circularity and is part of the solution to eliminating plastic pollution and reducing carbon emissions.

Our approach

In February 2022, The Coca-Cola Company (TCCC) announced its goal to have at least 25% of its global volume sold in returnable-refillable glass or plastic bottles or reusable containers through fountain or dispensers by 2030. This goal, which was set with input from the Ellen MacArthur Foundation, builds on a strong track record with refillable packaging, especially in Latin America, Europe and Africa.

The Ellen McArthur Foundation has defined four models of reuse in terms of packaging ownership and whether a consumer needs to leave home to refill/return the packaging. We support this model as a wide scope of reuse enables geographical (e.g. transport distances for refill) and environmental factors (e.g. water usage) to be taken into account when assessing our packaging mix in different markets

For refillable bottles, modelling by the Carbon Trust shows us that the transport distance to wash and refill a bottle have a significant impact of the carbon footprint of that bottle. In markets where the geography necessitates a large transport distance, refillable bottles will often not reach an ‘environmental break-even point’ compared with a fully circular single-use bottle.

We are working to increase the share of reusable packaging in our portfolio and are conducting a deeper analysis of reusable packaging across our business to ensure we can monitor and report our progress.

Together with TCCC, we have initiated a cross system approach to drive innovation in returnable-refillable packaging and dispensed delivery models, offering consumers new ways to enjoy our drinks. This includes new returnable-refillable pilots in France and Great Britain and Compact Freestyle smart dispenser pilots in at-work and university environments. Our glass bottles in Spain are in returnable-refillable formats in hotels, restaurants and cafes (HoReCa) and we are making this shift in France too. In Europe, approximately 84% of our glass bottles were returnable-refillable in 2022). We also opened a new returnable-refillable packaging line in Germany.

As the majority of containers for use with dispensed equipment are bought directly by our customers, we are also supporting them as they explore refillable container pilots and innovation initiatives which will drive both the infrastructure and consumer behaviour change needed to increase the share of reusable containers with dispensed delivery solutions.

Why it matters

Using recycled material in our bottles and cans keeps valuable resources in the circular economy and helps us move away from the use of new materials, including virgin fossil-based plastic. Recycled content in beverage packaging is also one of the key drivers of carbon reduction in beverage packaging – for example: 100% recycled PET has up to a 70% lower carbon footprint than virgin fossil-based PET.

Our approach

At CCEP, we want to do more with less when it comes to our plastic bottles. This is why we have set a target to include 50% recycled plastic in our PET bottles by 2023 (Europe) and 2025 (API) and to stop using oil-based virgin plastic in our bottles by 2030.

We have made significant investments to increase our use of recycled plastic (rPET) and are making good progress. We use 100% rPET across our entire local portfolio in Iceland, the Netherlands, Norway, Sweden, Belgium and Luxembourg and 100% rPET in our single serve bottles in Germany, Great Britain, Australia, Fiji and New Zealand.

There are two categories of recycling methods for plastic – mechanical recycling and chemical recycling.

Today, mechanical recycling is the most energy efficient recycling process with the lowest carbon impact, which is why it's our primary approach for PET. However, due to the way PET behaves when it is mechanically recycled, it cannot be the only recycling process used if we want to achieve a closed loop, circular economy for PET at scale for the whole industry. There will also be a need to scale chemical recycling to both close the loop on our PET bottles and to start to use recycled plastic in our bottle caps. Read more about our vision for closed loop circular PET .here

We have worked on what this ‘bottle of the future’ may look like in closed loop, circular economy and we foresee PET sources being a combination 70-80% from mechanical recycling and 20-30% ‘like-virgin’ PET from short loop chemical recycling technologies (like depolymerisation recycling) or renewable sources. Through our investment arm, CCEP Ventures, we are supporting technical innovation in short loop chemical recycling by funding CuRe Technology.

It is important to note though that, while some bottles contain 100% recycled content already, no market is yet in an entirely closed loop, circular plastic system.

Recycling infrastructure that can effectively sort and recycle PET is only one of three critical factors that need to be in place to increase rPET production. We need to ensure that beverage packaging is designed for circularity and the right collection solutions must also be in place to ensure high quality feedstock for the recycling process.

Collection solutions vary depending on the socio economic and legislative context in each country. In markets where collection infrastructure is often well developed and beverage packaging return schemes are in place, CCEP advocates for priority fair access to the collected PET material. This will drive better circular outcomes for PET by building bottle-to-bottle recycling loops and avoiding high quality PET being downcycled into low value plastic and being lost from the circular loop.

Why it matters

Chemical recycling refers to a family of recycling technologies that turns plastic back into its smaller components from which the plastic polymer is made. This enables plastic that is currently hard to recycle via mechanical recycling to be recycled back into plastic that can be used again, including for food grade applications.

How chemical recycling works:

Plastic is a polymer which means it is a substance which has a structure built up from a large number of identical units – molecules or small chemical compounds known as monomers bonded together via chemical reactions. This process is known as polymerisation.

The polymerisation process that makes plastic can also be reversed via chemical recycling, which breaks the chemical polymer structure back into its smaller components. This ranges from going back to oligomers (chains of monomers) or monomers or all the way back to the basic hydrocarbons.

There are two broad categories of chemical recycling technologies:

Short loop chemical recycling - these recycling technologies are suitable for polymers where the chemical bonds that hold the plastic together are easy to break (e.g. PET). It means that only a few steps are needed in the process to produce recycled plastic.

Long loop chemical recycling - these recycling technologies are suitable for polymers that have chemical bonds that are harder to break (e.g. polyolefins). To recycle this plastic, the polymer is broken down to basic chemicals products or oils. To make new plastic products, more steps are needed in the process than short loop chemical recycling and these steps produce multiple outputs in the production of new plastics (e.g. plastic, other chemical compounds, fuels).

Chemical recycling technologies can increase the amount and types of plastics that can be recycled back to food grade quality plastic and are a key enabler of creating a circular economy for plastic for two reasons:

- Mechanical recycling is the most energy efficient recycling process for PET - the plastic that is used to make our bottles – back to a food grade quality plastic. However, some PET, such as opaque, coloured or contaminated PET, and other plastics, like the ones used for our closures and labels, are hard to recycle back into food grade plastic via mechanical recycling. A chemical recycling approach is therefore needed to maintain the material value of this plastic and keep it in the circular economy.

- Due to the way PET behaves when it is recycled mechanically, a need will remain for around 20% virgin PET in any closed loop system until it can be replaced by PET that has been recycled back to a ‘like virgin’ state via chemical recycling. You can read more here. on our vision for a low carbon, circular economy for PET bottles in our markets, removing virgin fossil-based PET in PET bottles.

Our approach

For plastic that is hard to recycle back to food grade plastic via mechanical recycling and to drive progress towards circularity, we are supporting the scaling of chemical recycling technologies via investment and collaboration.

As with all technology, the impact of chemical recycling will depend on how it is implemented. CCEP is committed to the responsible and transparent use of chemical recycling technologies and is support the World Wildlife Fund’s guiding principles for their application.

To maximise environmental benefits and to ensure that plastic isn’t diverted from a more energy efficient recycling processes, we believe that plastic should only be broken down into its chemical building blocks as far as is necessary to recycle the plastic effectively and efficiently so that it can have a material value returned. To find out more about this approach, see our recycling technologies framework.

Chemical recycling technologies are currently at an early stage of development and the Coca-Cola system – both Company and bottlers - is investing to bring short loop chemical recycled material to commercial scale. An example of this is Ioniqa, a full depolymerisatiion (AKA enhanced) recycling process through which previously unrecyclable or hard to recycle plastic can be transformed to the building blocks needed to create new, food grade quality PET. Another is CuRe, a partial depolymerisation process that transforms hard to recycle and opaque food grade PET back into new food grade PET. Once the CuRe technology is commercialized, CCEP expects to receive the majority of the output from a CuRe-licensed, new build plant.

Removing unnecessary packaging

We’re removing all unnecessary packaging, including via lightweighting and removing hard to recycle packaging. And we’ll make sure that 100% of our packaging is recyclable or reusable.

In 2023, 99.1% of all our packaging was recyclable. By 2025, we will ensure that all of our primary packaging, including the cartons and pouches we use for some of our drinks, is fully recyclable and compatible with local packaging collection infrastructure. This is aligned with The Coca-Cola Company’s global pledge to use 100% reusable or recyclable packaging as part of its World Without Waste strategy.

More about reducing and removing packaging

Replacing plastic with cardboard

In 2021, we continued to roll out CanCollar® packaging technology in the Balearic Islands in Spain, KeelClip™ in France and a carton solution in GB, using 100% sustainably sourced, fully recyclable cardboard. These programmes enabled us to remove around 2,000 tonnes of hard-to-recycle plastic from our secondary packaging.

In 2021, we continued to roll out CanCollar® packaging technology in the Balearic Islands in Spain, KeelClip™ in France and a carton solution in GB, using 100% sustainably sourced, fully recyclable cardboard. These programmes enabled us to remove around 2,000 tonnes of hard-to-recycle plastic from our secondary packaging.

Making our packs lighter to save energy and resources

We have a long-standing programme to reduce the weight of our packaging and optimise the materials we use.

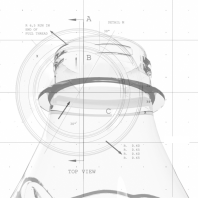

In 2008, a 500ml PET bottle weighed 28.9g. Today, thanks to innovative work with our suppliers, this same bottle now weighs just 19.9g, and current projects will reduce this further. Read more here.

In 2023, we continued to shift our can portfolio from steel to aluminium in Europe. As aluminium is lighter than steel, by replacing around 360 million steel cans with aluminium we eliminated approximately 9,000 tonnes of CO2e in 2023. In API, we only use aluminium cans.

Innovating in refillable and dispensed solutions

We’re innovating in refillable and dispensed solutions as a key strategic route to eliminate packaging waste and reduce our carbon footprint.

By 2030, The Coca-Cola Company aims to have at least 25% of all beverages globally across its portfolio of brands sold in returnable glass or plastic bottles, or refillable containers through traditional fountain or Coca-Cola Freestyle™ dispensers. In 2021, together with The Coca-Cola Company, we initiated a cross system approach to drive innovation in refillable packaging and dispensed delivery models, offering consumers new ways to enjoy our drinks.

More about refillable packaging and dispensers

Returnable glass bottles for hospitality customers

In Germany we are boosting the availability of at-home refillable drinks options by expanding our returnable glass bottle (RGB) portfolio, switching to a universal bottle. In 2023, we introduced 1L RGB for our Fanta, Sprite, Mezzo Mix, Vio Bio Limo and Fuze Tea brands.

We actively promoted refillable packaging through a consumer campaign creating awareness on our PET refillable portfolio. Over the last five years, we have significantly invested in reusable bottles, including two new refillable glass bottling lines and new reusable crates.

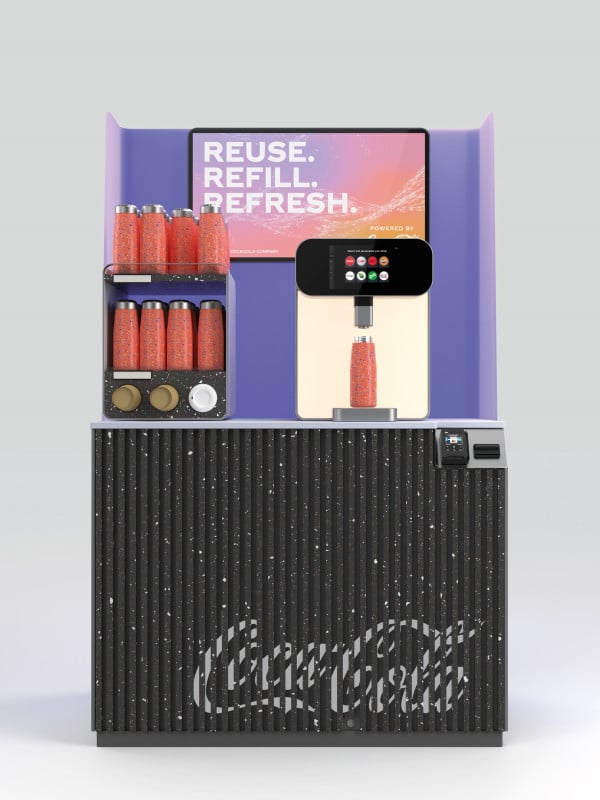

Fill your own reusable container from Freestyle

New Compact Freestyle drinks dispensers have been developed with The Coca-Cola Company in Europe, as an extension of the iconic Coca-Cola Freestyle brand and portfolio. Designed for smaller on the go and at work locations, it allows consumers to personalise their drink choices and choose to fill their own reusable vessel.

The smart dispenser offers consumers greater choice and personalisation with over 40 beverage choices, and is being trialled in five of CCEP's markets in Europe.

Achieving 100% collection

We aim to collect the equivalent of all our packaging so it can be recycled and reused.

We are committed to accelerating our work to support an economy where packaging materials are collected and recycled in all our markets. We are working with national and local governments and stakeholders across all our countries of operation to develop and fund collection solutions that provide good quality recycled plastic, while also reducing packaging waste, including packaging that is littered or goes to landfill or incineration.

More about packaging collection

Collecting through packaging return schemes

In markets where collection infrastructure is often well developed, like Europe, Australia and New Zealand, we support legislation for well designed, industry-run beverage packaging return schemes.

In markets where collection infrastructure is often well developed, like Europe, Australia and New Zealand, we support legislation for well designed, industry-run beverage packaging return schemes.

Schemes are in place in Norway, Sweden, the Netherlands, Iceland, Germany and some states in Australia. We continue to advocate for well-designed Deposit Return Schemes in our other European markets. In New Zealand, we have been actively engaged with the Government for over two years on the development of a Container Return Scheme (CRS) and welcome the announcement of a proposal to implement a nationwide, industry-led scheme by 2025.

Taking voluntary action to collect packs and support communities

In Indonesia, collection is mainly driven by the informal waste sector, so our approach is centred on social enterprise and community support. As part of our plastic recycling plant joint venture with Dynapack we established Mahija Parahita Nusantara. As a non-profit foundation, it works to improve the lives and welfare of 3,500 waste pickers working in the informal waste sector through the development of collection micro-enterprises. The waste pickers collect high quality feedstock for the recycling plant. We assist the informal waste picker communities with health checks, living staples and education.

The power of our brands and our people

We continue to use the power of our brands to encourage consumers to recycle our packaging via on pack messages.

In Norway, we ran a nationwide campaign in 2022 in partnership with the Norwegian Football Federation, highlighting the importance of collecting bottles for recycling. The campaign resulted in the collection of €84,000 worth of empty bottles.

In Sweden, we started a new joint initiative with NGO Keep Sweden Tidy and customer Reitan Convenience, to raise awareness about recycling and reuse, and encourage more people to recycle on the go.

We also support a wide range of anti-litter and clean up initiatives through local community partnerships and employee volunteering. As well as removing and preventing litter, these activities influence consumer behaviour and raise awareness about litter and recycling.

Increasing recycled content

Using recycled material in our bottles and cans keeps valuable resources in a circular economy and reduces our use of new materials including fossil-based plastic.

We’ll make sure that 100% of our primary packaging is recyclable or reusable. We’ve hit our target of ensuring that at least 50% of the material we use for our plastic bottles in Europe comes from recycled plastic, and we're hopeful we'll reach this by 2025 in other markets.

We are investing in new technologies, like enhanced recycling, and engaging in partnerships to ensure a reliable supply of high quality rPET in all our markets.

A circular economy for plastic

We are moving towards 100% recycled or renewable PET in our plastic bottles, replacing our use of new fossil-based plastic as we do so. This is one small step in a much bigger industry journey towards plastic packaging circularity.

More about sustainable packaging

How we’re using recycled plastic in our bottles

All locally produced bottles in Sweden, the Netherlands, Iceland and Norway and single-serve bottles across Belgium, Germany, GB, Australia and New Zealand are now 100% rPET. We continue to make further transitions to rPET including in France, Indonesia and Fiji. Our increased use of rPET in Europe has saved around 34,000 tonnes of CO2e since 2019.

All locally produced bottles in Sweden, the Netherlands, Iceland and Norway and single-serve bottles across Belgium, Germany, GB, Australia and New Zealand are now 100% rPET. We continue to make further transitions to rPET including in France, Indonesia and Fiji. Our increased use of rPET in Europe has saved around 34,000 tonnes of CO2e since 2019.

Scaling up plastic recycling capacity

Demand for high quality food grade plastic currently exceeds supply. We are investing in long term partnerships with recyclers to stimulate their investment to scale up recycling capacity, and making our own direct investments.

Demand for high quality food grade plastic currently exceeds supply. We are investing in long term partnerships with recyclers to stimulate their investment to scale up recycling capacity, and making our own direct investments.

Read more about how we're scaling up recycling capacity here

Investing and innovating for the future

Innovation is an important pillar in our strategy. We’re investing in the development of new technologies to support our plan. We’re pioneering sustainable packaging – including refillable and dispensed delivery models, new ways to reduce packaging waste and renewable materials.

Our Sustainable Packaging Office (SPO) streamlines all the technical and exploratory sustainable packaging work across our geographies, accelerates our innovation and supports progress towards our goals.

CCEP Ventures, our innovation investment fund, supports the SPO by providing early stage funding to technologically advanced companies and start ups that, among other things, enable us to explore new ways to bring sustainable packaging innovation to life. Find out more about our investments.